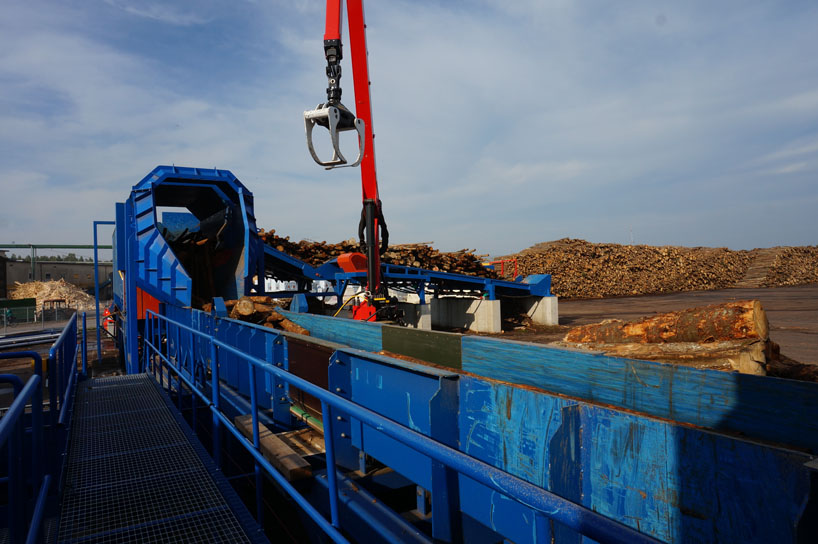

Low-grade logs debarking lines

Debarking lines for low-grade logs are mainly designed for debarking and chipping pulp wood, extremely curve logs or logs, which cannot be used for mechanical woodworking for any other reasons. Such logs are to be chipped for further processing.

Singulated log feeding is not required here. The line is specially designed for debarking of heterogeneous batches, its capacity being 30-70 m³ of logs per hour, depending on the debarker and the chipper capacity and desired debarking quality.

The structure of the line main machine comprises three rotating rotors with debarking teeth and a bark removal conveyor under the debarker. Logs of different diameters are fed to the debarker from above – from log deck and elevator normally used at sawmills. The machine rotors constantly turning in one direction rotate the logs and push them up and down. Due to logs rub against each other and their contact with abraders (rotor teeth) logs debarking is performed. The removed bark falls to a bark conveyor placed under the debarker through special slots.

Debarking quality is regulated by the amount of logs fed to the debarker and debarking time. For that hydraulically adjustable shield is used. Over the shield logs are dropped to conveyor to be transported to further processing. Depending on the season, debarking quality can also be regulated by means of adjusting (by hydraulic jack) the angle of the debarking machine position.

Barked logs are fed with chain conveyor to chipper, with chipper type and capacity to be used depending on customer’s requirements.